Do you need help? Contact us:

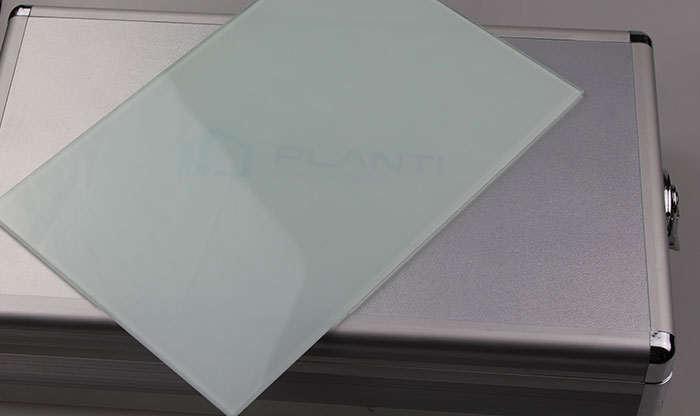

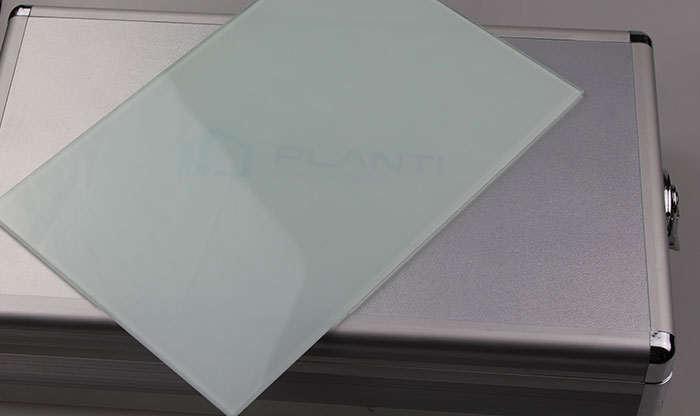

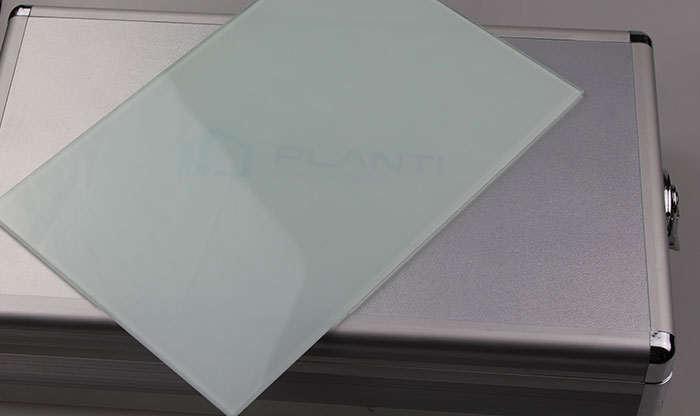

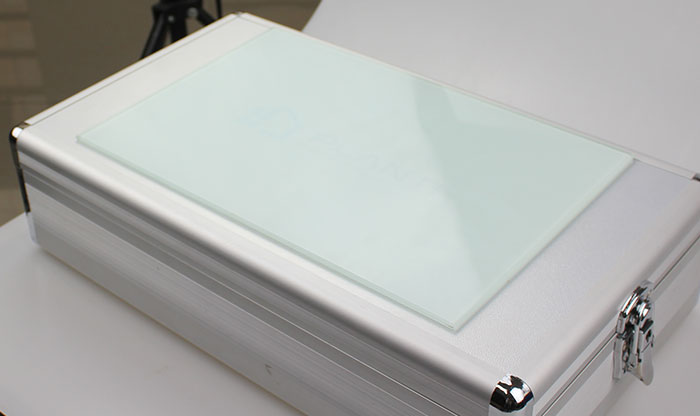

White-coated glass is a clear-based product; the white painting can be pretty hard by brushing the white artwork on the glass surface before tempering. The painting process is crucial to producing white glass; at PLANTI, we process painting in a dust-free workshop to ensure a uniform, flat surface. Of course, the recipe for white painting is also very essential. White glass is usually used on the packing facility roof of a greenhouse, and there are many more strict requirements to produce greenhouse used white glass compared with white glass used as building walls. This is because any appearance defects will be easily shown if the white glass is installed on the roof.